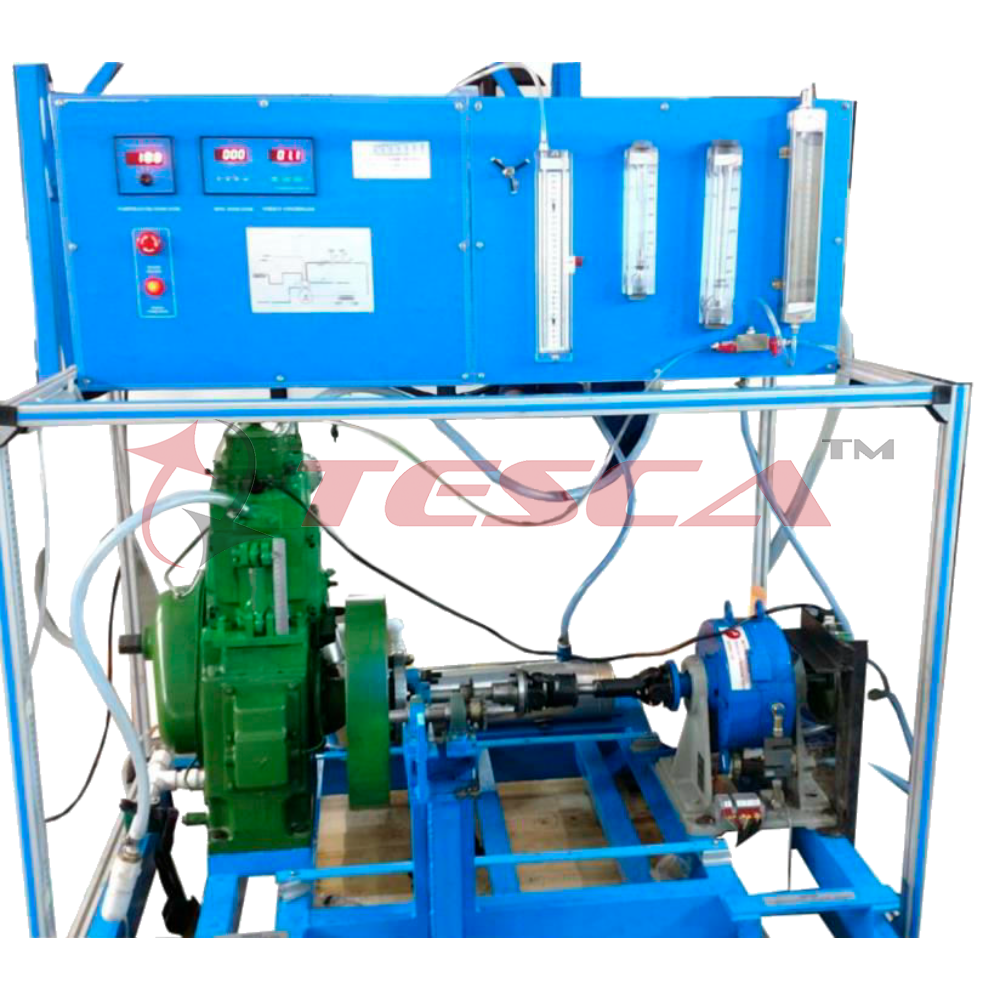

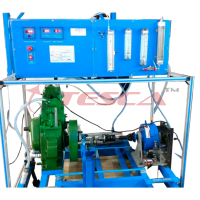

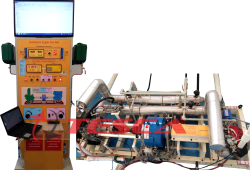

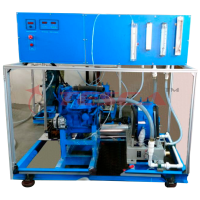

Single Cylinder Petrol Engine with Variable Compression Ratio With DAQ

Order Code: 32730

Category: Technology Trainers

The air-cooled single-cylinder four-stroke petrol engine is identical in design to the four cylinder engine. A modified cylinder head permits additional experiments with various combustion chamber inserts. To adjust the mixture composition, the carb...

SPECIFICATION

The air-cooled single-cylinder four-stroke petrol engine is identical in design to the four cylinder engine.

A modified cylinder head permits additional experiments with various combustion chamber inserts. To adjust the mixture composition, the carburetor was modified.

32729-32730 are fitted with a special device to adjust the ignition timing - from advanced to retarded.

The engine includes a sensor to measure the exhaust gas temperature. The sensor, ignition cut-off and fuel supply are connected to the test stand.

System Description

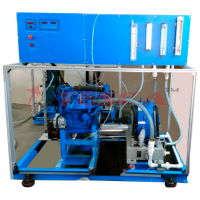

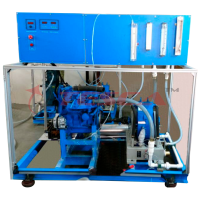

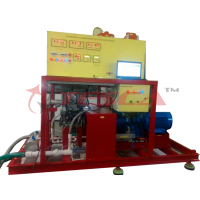

Components of System:

1. Base stand – It is made up of Mild steel structure as per the system configuration on which all components are mounted. “C-channels of 50x100 mm and Angles of 50x50 mm have been used. This is painted specially with powder coating

2. Aluminum structure – It is made up of extruded aluminum section of having cross-section 30x30 mm. A panel is mounted on the aluminum structure.

3. Engine – Engine is mounted on the base frame which is coupled to the eddy current dynamometer. This engine has the following specifications:

No. of cylinders : 1

No. of Strokes : 4

Type of cooling : Water cooled

Fuel used : Petrol

Power : 5 Hp/3.7 KW

RPM : 1500

Cubic Capacity : 0.481 ltr

Bore diameter : 87.5 mm

Stroke length : 80 mm

VCR Range : 12 to 18

4. U Tube Manometer- This trainer consists of a U-tube manometer made up of acrylic. It has 2 tubes, both being short at their bottom to measure suction pressure of engine for air. Manometer used in this setup has range of 0-300 mm. Scale provided with it makes it easy to take reading.

Specifications:

Range: 0-300 mm

No. of tubes:2 tubes

Material: Acrylic

5. Fuel Meter – It is made up of acrylic and mounted on the main Panel on the right hand side. It is used to measure the fuel consumed by engine in particular time interval. It has got range of 0 to 230 mm. It is connected to the manifold through a mini ball valve which is used to control the flow

Specifications

Range: 0-230 ml

Material: Acrylic covered by metallic shield

6. Rotameter– It is made up of acrylic block which is used to measure flow rate of water through calorimeter.

Specifications:

Range: 0-1000 LPH

Material: Acrylic

Pipe size inlet and outlet: 12.5 x12.5 mm

7. Rotameter : This Rotameter is use for measure the water supply in engine jacket

Specification:

Range: 0 to 3000 LPH

Material: Acrylic

Size:25.4×25.4 mm

8. Calorimeter–It is mounted on the base frame and powder coated. It is a shell and tube type heat exchanger in which exhaust gas exchanges heat with water. It is to measure heat of exhaust gas. Temperature sensors are mounted on it to measure the temperatures of the exhaust gas.

Specifications:

Type of Heat exchanger: Shell and Tube

Hot Fluid: Exhaust gases

Cold Fluid: Water

Pipe Size inlet and outlet: 19mm

9. Load Cell Unit: Load cells are differential type transducers which give the readings according to their displacement. They made of anodized aluminum having a shape of English alphabet “S”. The output generated by the load cell can be directly read from the load indicator. The load cell arrangement is done as shown in the photo. Tension type of the load cell is used for measuring the load given to the dynamometer. The load cell indicator is given on the control panel with the zero setting buttons such that we can adjust zero for measuring the load given to the dynamometer.

Specifications:

Capacity: 150 Kg

Accuracy: 0.01 Kg

Button: Set zero and span with converter

Type: Compression and tension (S type)

10. Temperature Sensors and Indicator – They are 3 wire temperature sensors with 3 inch stainless steel probe and 1 m cable length. They are used to measure the temperature and connected to the temperature indicator which shows the reading in unit 0C

Specifications:

Element Type: Platinum

Diameter: ¼ inch

Resistance at 0o C: 100 ohms

Fitting Material: Stainless Steel

11. Rpm Sensor and Indicator- It is a inductive proximity sensor which is used to measure the rotation per minute of the shaft. It is robust in construction and detects the rotation of the screw mounted on the shaft. Output of RPM sensor is given to RPM indicator which shows the angular speed of the shaft in RPM.

Specifications:

Type: Inductive proximity (PNP type)

Range: Auto ranging (4 to 9999 RPM)

Accuracy: 0.05%

Sensor supply: 12 VDC, 30 mA

Operating temperature: 0 to 50 0c

Humidity: 95% RH

12. Air tank– It is made of mild steel and powder coated. An orifice is provided on one side and the other side is connected to engine air suction through a flexible hose. It is mounted on the aluminum structure. A pressure tapping is provided on it to measure the mass flow of the air sucked by engine

13. Manifold - It is made of acrylic block with 1 inlet and 2 outlet. It takes fuel from its inlet from fuel tank and gives it to fuel meter from it outlet. Ball valves are provided for that reason.

Specifications:

No of ports: 3

Size of fitting: ¼ inch

Material: Stainless steel

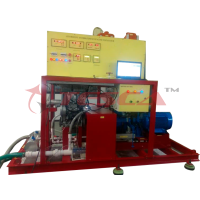

14. Eddy current dynamometer:

A dynamometer, or “dyno” for short, is a machine used to measure torque and rotational speed (rpm) from which power produced by an engine or any other rotating prime mover can be calculated. Dynamometers are used for measurement of brake power. To measure brake power, the engine torque and angular speed have to the measured. The rotor is driven by the engine under test by mechanical, hydraulic or electromagnetic means. The rotor is coupled to the stator. For each revolution of the shaft rotor covers the distance 2×R×F against coupling force F.

Work done = 2× ×R×F

15. Vibration Pads– These are anti-vibration mountings which are round in shape. These are fitted to the base frame with nut bolting.

16. Piping: Piping is done in UPVC and flexible hose. The ball valves are provided to control the flow rate.

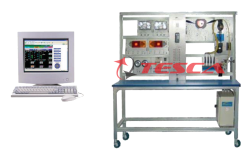

Optional:

Computer interface available

- 4-channel diagnostics, computer, monitor, printer set of Interface System

- Input, control function for real-time system and input, output, diagnosis, saving of data can be done by PC interface. By inspecting circuit diagram standard value and graph, it can be efficiently done by comparison and analysis of education.

- By directly providing breakdown to ECU or actuator control with PC and equipment, it measures data of before and after period of breakdown.

- Grasps the condition of module's signal transmission and related components with additional function, which includes input/output measurement diagnosis of ECU and all sensors, and automatic setting of voltage and time division.

- Input and output of ECU and actuators, manually controllable with control connection system and it can be measured easily on multi-meter and oscilloscope

- Measuring probe and adaptor can be provided for equipment use.

- Auto Sci-Cal® Engine Cycle Analyzer Module AMECA (Optional)

Features

- Significantly enhances practical investigations, demonstrations and studies of internal combustion engines

- For use with Smaller capacity Engine Test Sets and Regenerative Engine Test Set and engines

- Factory fitted with suitable cylinder head transducers and crank angle encoders

- Includes powerful Windows based software specially designed for educational use

- Automatic calculation and real-time display of p-q plots and p-V plots and other important parameters

- Useful snap-shot, replay and animation functions

- Accurate, clear animations of crank, piston, inlet and exhaust valve positions help students visualise the engine cycle

- Ideal for student experiments, laboratory demonstrations or project work, Engine Cycle Analyzer enables students to investigate a variety of engine performance characteristics.

- Students can export data for further analysis

Tesca Auto Sci-Cal Engine Cycle Analyzer Module AMECA is a module with hardware and software to measure internal combustion engine cylinder pressure and crank angle.

Tesca AutoSci-Cal Engine Cycle Analyzer Module AMECA is a versatile module consisting of both hardware and software specially designed for educational use. It enables students to investigate the relationship between crank angle or volume and the cylinder pressure in an internal combustion engine. The equipment is primarily for use with engine test sets and engines but it can also be used with other engines fitted with compatible cylinder head transducers and crank angle encoders.

The equipment consists of a hardware unit with connectors and leads, plus Windows based data acquisition and analysis software. The hardware consists of a microprocessor-based signal conditioning unit with high-speed PC interface, housed in a rugged, protective enclosure. It accepts and conditions signals from the Cylinder Head Pressure Transducer and Crank Angle Encoder, pre-mounted on the engines. The cylinder pressure input includes a precision charge amplifier with a digital calibration. Crank angle position, the signal from the Crank Angle Encoder is also used to determine engine speed.

The output from the hardware unit connects to a computer (computer not included) running the Engine Cycle Analyser software. The hardware unit includes LED indicators to show the processor readiness, encoder top deadcentre position and PC communication status.

The software provides real-time display of pressure versus crank angle (p-q) and pressure versus volume (p-V) plots.

It performs calculations on the data to accurately display indicated mean effective pressure (IMEP) and indicated power for comparison with brake mean effective pressure (BMEP), and brake power to determine the mechanical efficiency of the test engine.

The software has useful snap-shot, replay and animation functions to help students visualise and better understand the engine cycle. The snap-shot and replay allow students to capture several engine cycles and study them using an animation showing the relative position of the crank, piston, inlet and exhaust valves. The software also allows students to create and recall engine configuration files for convenient entry of test engine data needed for calculations such as crank radius and engine swept volume. Data can also be exported to other software for further analysis.

Experiment Possibilities

- Module AMESA allows investigations into a variety of internal combustion engine characteristics, including:

- The thermodynamic cycle of an internal combustion engine

- Calculation of indicated mean effective pressure and indicated power

- Comparison of indicated mean effective pressure and brake mean effective pressure

- Mechanical efficiency of the test engine

- Further work using exported data such as combustion analysis

Extra Ancillaries (fitted on engines)

Cylinder Head Pressure Transducer

Crank Angle Encoder

Recommended computer hardware:

Intel® Pentium® 4 or equivalent processor operating at 2 GHz

512 MB of RAM

SVGA monitor with 16-bit colour, 1024 x 768 resolution

CD-Rom drive

USB 1.1 or 2 port

500 MB of hard disc space

Two-button mouse

Operating system:

• Microsoft® Windows XP, Vista, Windows 7 and 8

Standard Features

Supplied with comprehensive user guide

Made in accordance with the latest European Union Directives

Requirements:

Electrical supply:

Single-phase a.c. 90 to 240 V, 50/60 Hz

Operating Conditions

Operating environment: Well ventilated laboratory

Storage temperature range: –25°C to +55°C (when packed for transport)

Operating temperature range: +5°C to +40°C

Operating relative humidity range: 80% at temperatures < 31°C decreasing linearly to 50% at 40°C

91-9829132777

91-9829132777